| T O P I C R E V I E W |

| ZLM |

Posted - 06/26/2010 : 21:22:12

The steps to remove and then solder back a SMD chip. Following tools are used:

1. a 2-in1 rework station (TOOL-021)

http://www.mcumall.com/comersus/store/comersus_viewItem.asp?idProduct=4393

2. SMD rework essential pack (TOOL-031)

http://www.mcumall.com/comersus/store/comersus_viewItem.asp?idProduct=4446"

Remove Steps:

1. Prepar the SMD rework station

Adjust temperature to 350 degree C on both hot air and iron.

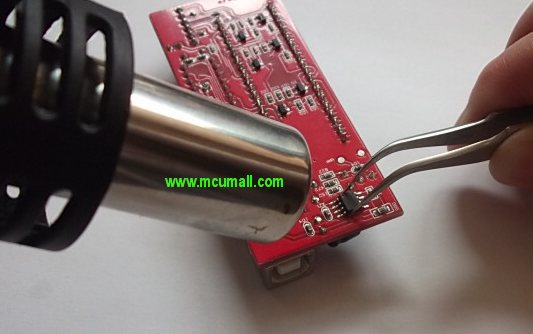

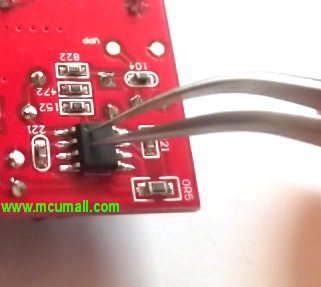

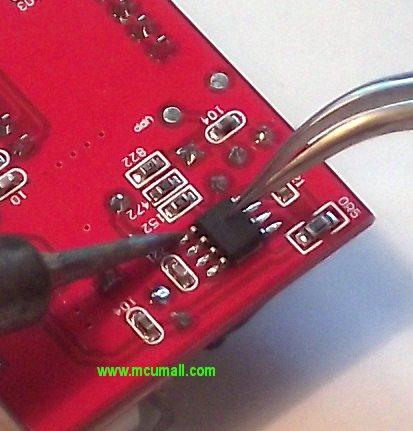

2. Use hot air to heat the chip and remove the chip using the tweezer.

3. Chip removed

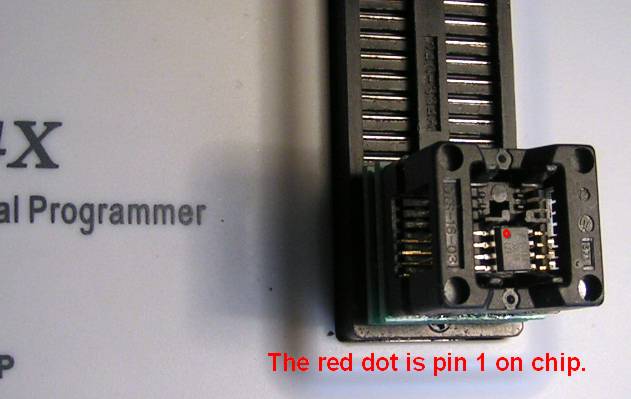

[b]4. Plcae the chip in adapter for read/write on programmer

|

| 13 L A T E S T R E P L I E S (Newest First) |

| machack |

Posted - 01/09/2013 : 19:09:21

WOW you make it look so easy! |

| ecumotic |

Posted - 12/10/2012 : 21:46:23

you can use a little bit of solder on the pads but make sure the solder is clean. it should be silver looking and shiny and make sure to remove any excess. one thing after soldering your eeprom on the board, use a meter to check if any pins are shorting or making contacts.

quote:

Originally posted by benaknoun

Hi ZLM, sorry me again...

When i place the hot air gun and desolder the chip, there isn't much solder left on the pads sometimes, what is the best way to avoid this?

Thanks

|

| ecumotic |

Posted - 12/10/2012 : 21:44:03

if you dont have a display for temperature, you will have to be on the safe side while guessing. one tip is to have a piece of paper next to you and use the hot air gun on the paper. if it burns too quickly, then it is too high temperature.

the ideal is it should burn with a brown dot and slowly turns darker... |

| ZLM |

Posted - 02/15/2012 : 00:02:21

The SMD chip does not need much solder on the pad. As long as you can see the solder on the pad, it is enough.

If the solder is completely off, just use the soldering iron to put some solder. |

| benaknoun |

Posted - 02/06/2012 : 16:23:26

Hi ZLM, sorry me again...

When i place the hot air gun and desolder the chip, there isn't much solder left on the pads sometimes, what is the best way to avoid this?

Thanks |

| ZLM |

Posted - 02/05/2012 : 12:04:26

On GQ-5200, the 30% is abount on marker 4.

However, to select the correct air volume, the good position should not see the hot air element in red.

So, adjust volum from low to high untill the element not in red.(little dark red should be fine.) |

| benaknoun |

Posted - 02/04/2012 : 04:14:28

quote:

Originally posted by ZLM

The air volume normally is set to 30% position.

Hi ZLM

Thanks for your help, however, i have another question:

My hot air station has 2 setting, one for hot air temperature and one for air flow pressure

when i switch it on, the default setting of air pressure is 50, when i increase the temperature to 350, obviously the air pressure setting is too low and could damage the heat element, if you say 30%, do you mean i should set it to 105 ?

Thanks again |

| ZLM |

Posted - 02/03/2012 : 22:06:57

The air volume normally is set to 30% position. |

| benaknoun |

Posted - 02/03/2012 : 13:52:40

Hi

What is the ideal air pressure setting for 350 degrees temperature?

Thanks |

| ZLM |

Posted - 09/17/2010 : 18:54:22

If your rework station does not have digital display, then you need to estimate, |

| OCB |

Posted - 08/16/2010 : 12:03:09

Moi j'ai un AOYUE 850C comment ça voir que je suis a 350° vu que j'aipas d'affichage digital???

Le bouton HEATER je dois le mêttre a combien pour avoir 350°? Merci!!! |

| OCB |

Posted - 08/16/2010 : 12:00:15

Merci pour ce topic!!! |

| ZLM |

Posted - 06/27/2010 : 06:40:26

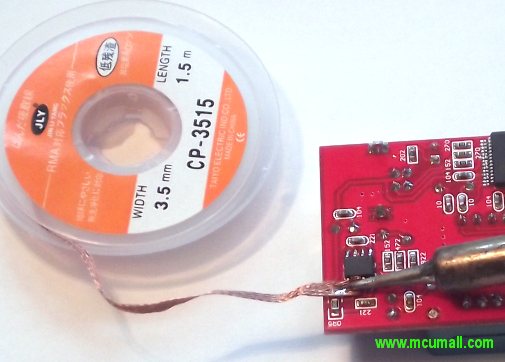

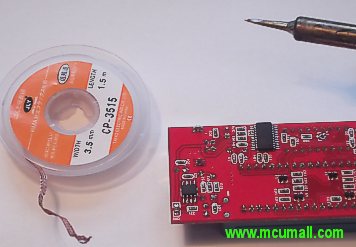

Solder the chip back Steps:

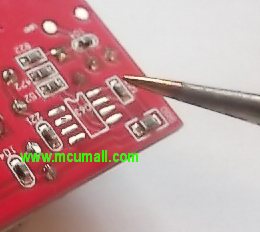

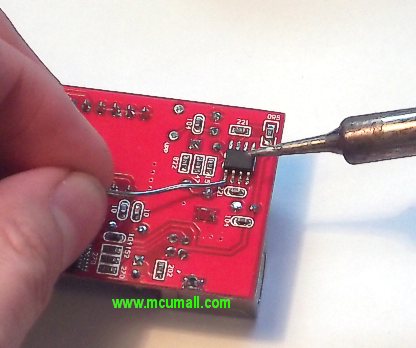

1.Clean the solder pad on PCB using the iron tip.

solder pad cleaned on PCB. All pad should have some solders and look shining.

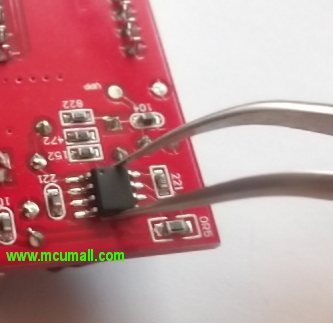

2.Place back the chip and position it using tweezer

3.Press the chip by tweezer and do not let it move once it is in postition

4.Solder a corner pin by pressing iron tip on it, so that you can remove the tweezer.

5.Then solder rest of pins using solder wire.

Do not worry about the pin briged by solder, it can be easily removed later.

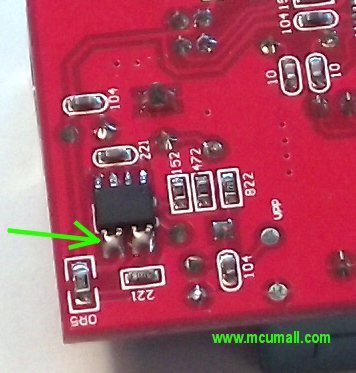

6. Remove the solder bridge between pins using desoldering braid / wick

[b]Solder bridge removed. You are done!!

|